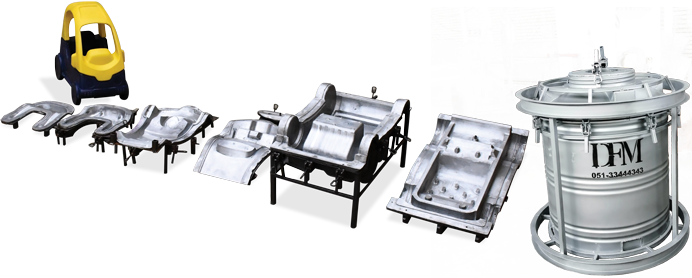

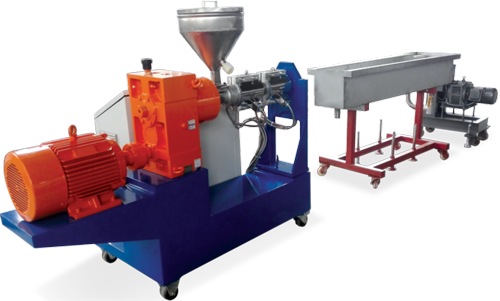

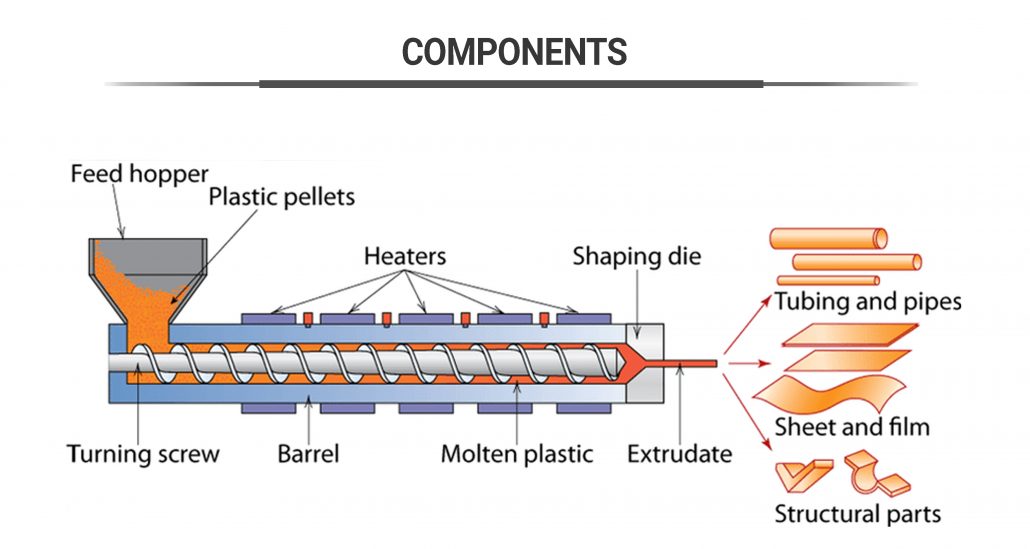

In extrusion, raw materials are fed into the machine, heated, combined, and propelled through a die to produce a wide variety of parts such as PVC profiles, plastic sheets, granules, and etc.

Extruders were invented in early 19th century. A wide variety of models have been made ever since but none were practically used in plastic industry.

It wasn’t until different variations of plastics came to the market in early 20th century that the first successful plastic extrusion was performed.

Today, extruders are widely applied in many different areas like metal, food, and plastic industries. In plastic industries they’re used to manufacture plastic pipes, PVC profiles, and electric hoses at any length. One good part about extruders is the low amount of wastes. Production wastes or defective parts can be reused which will significantly reduce economic losses

.

فارسی

فارسی