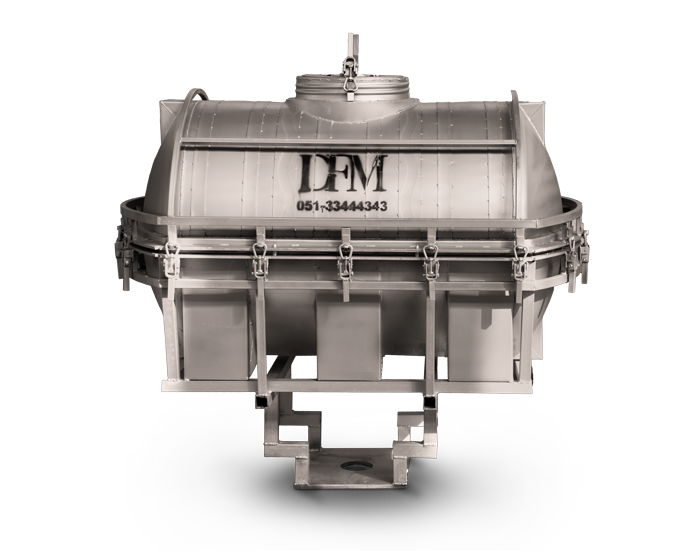

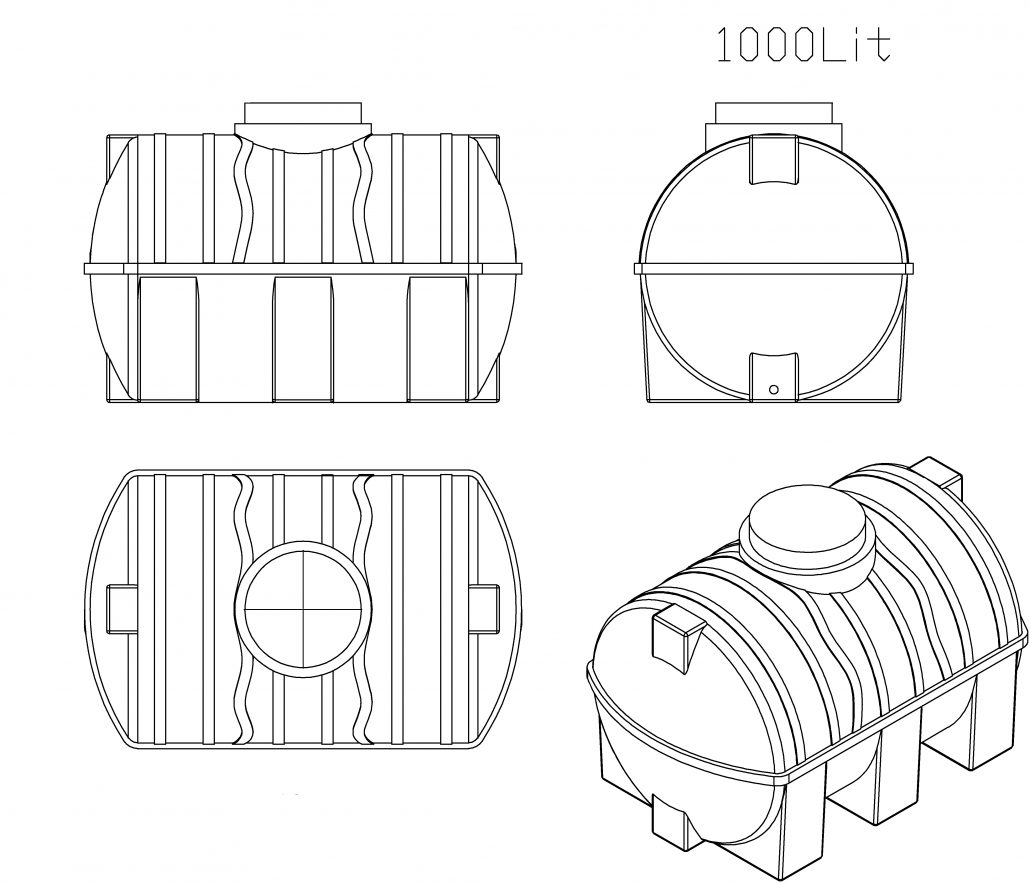

1000 Lit horizontal tank mold type B

The physical properties and cost of polyethylene make it a good choice, some of which are mentioned below:

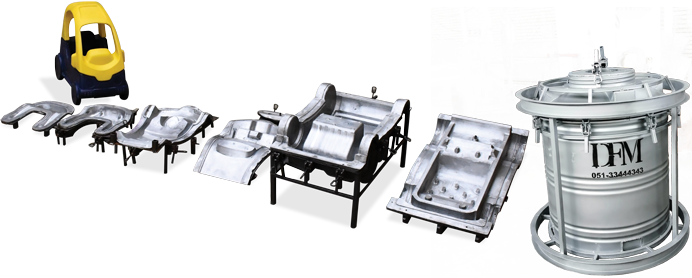

Horizontal tank’s mold is fabricated from iron sheets. The process of fabricating a mold starts with modelling the product. Then the sheets are sheared and shaped followed by welding them together. Inner mold surface is grinded and polished afterwards. As the final step inserts, clampings, and the frame are installed and the mold will be ready to use.

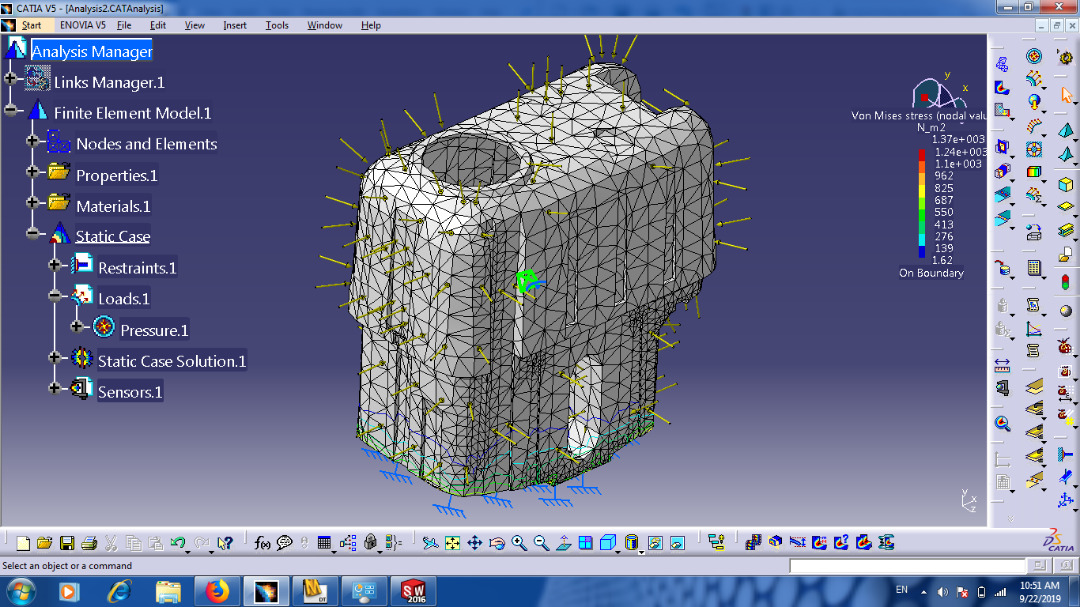

Decent ideas might come to your mind that have a great potential but to turn it into reality might just seem a bit too hard. At DFM Co., with more than 15 years of experience, alongside free business plan and feasibility studies, we will also aid you in making your ideas come to life. A sketch or a model of your idea will be received by our engineers. The design will be evaluated, utilized, and simplified in the next step. Followed by implementing FEA (Finite element analysis), product’s performance in real life conditions will be evaluated preventing possible design failures and fixing its flaws. The procedure is developed to be as cost efficient as possible by thoroughly analyzing the part before production.

فارسی

فارسی