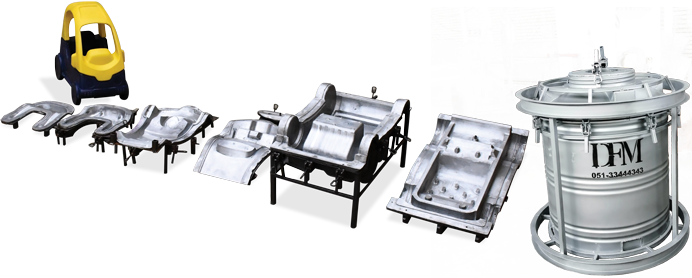

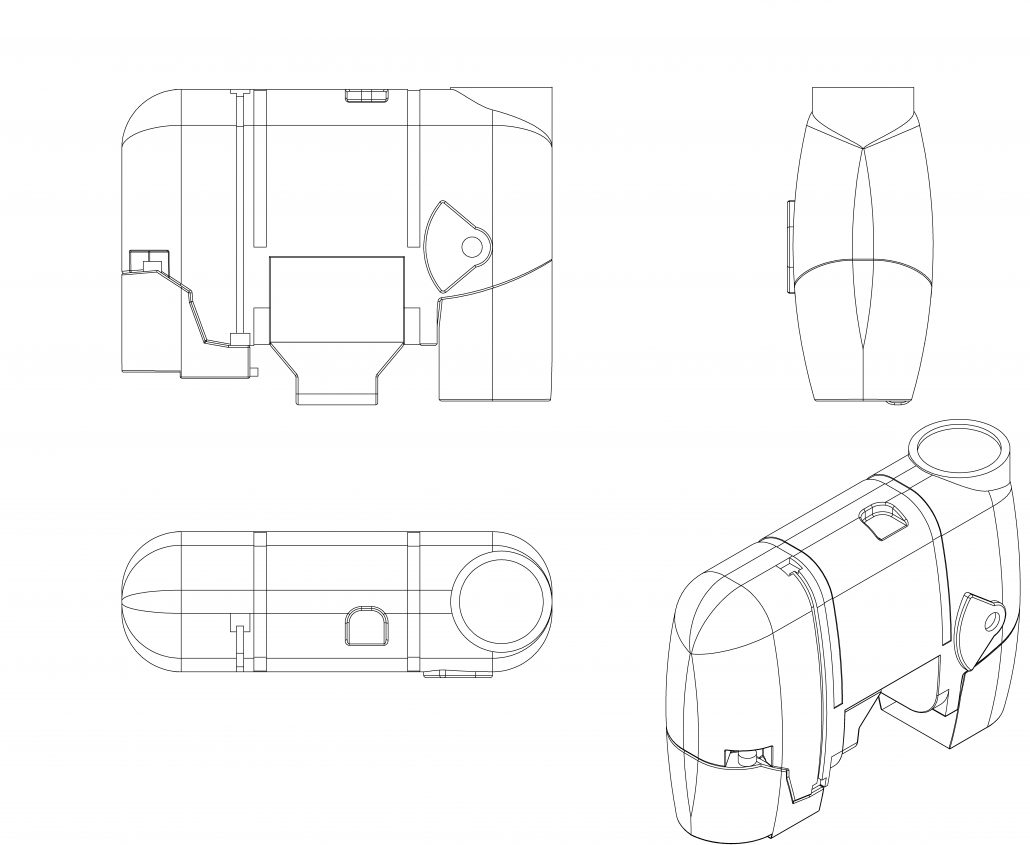

1200L mounted sprayer tank mold

Manufactured in Davaran Fidar Maham Co.

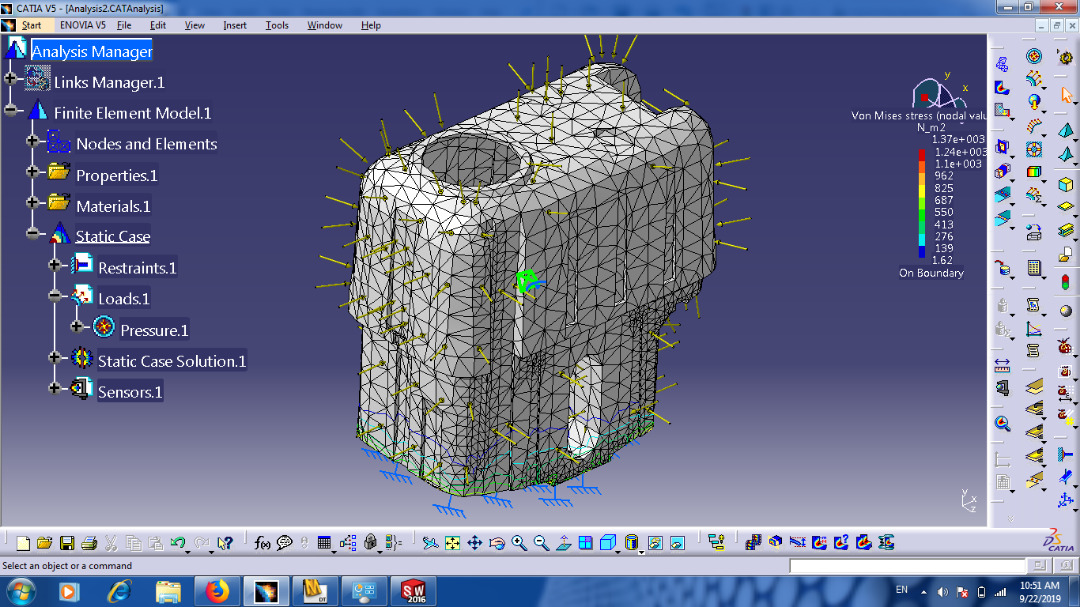

There are several methods and materials used in making molds. Each of which has their own unique method. The mounted sprayer tank’s mold is fabricated from iron sheets. The product is initially modelled and the sheets are sheared and shaped afterwards. Followed by welding the pieces together, the mold’s inner surface and welded areas are grinded and polished. Installing the inserts, frame, and the clampings will be the final step after which the mold will be ready to use

فارسی

فارسی