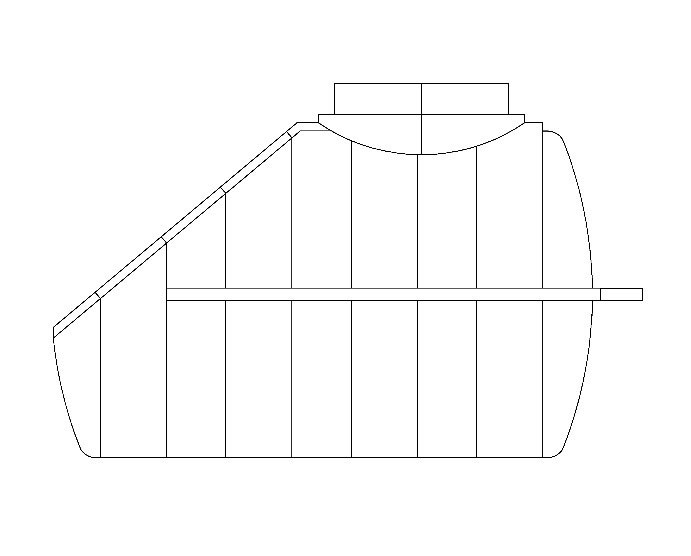

500 liter under stairs tank mold

Manufactured in Davaran Fidar Co.

Under stair tanks’ purpose, as it’s quite self-explanatory, is to fit the spare space under staircases

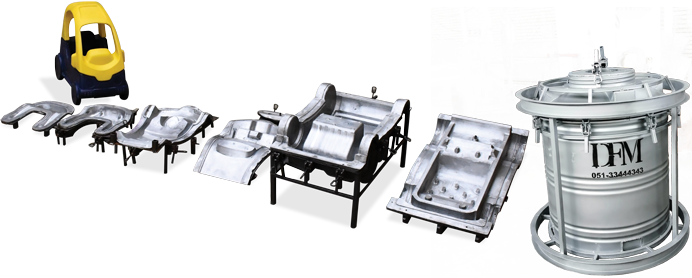

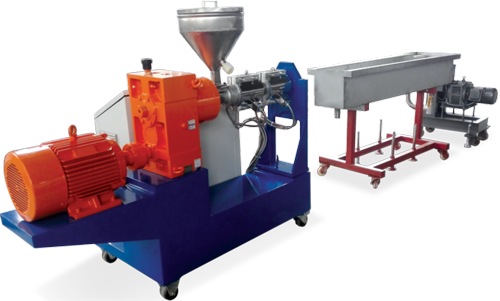

Rotational molded parts, when compared to parts manufactured via other plastic producing techniques, are way cheaper and also beneficial even in low volume productions. Suitable for manufacturing large hollow products, uniform wall thickness, custom surface textures, and different colors are also easily achieved in rotational molding.

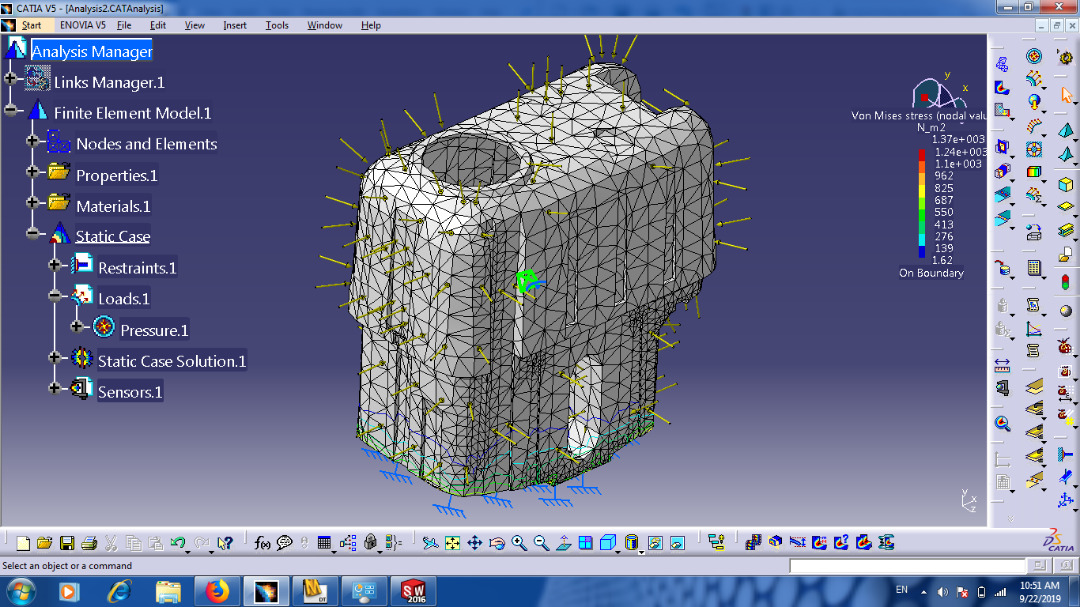

Under stairs tank’s mold is fabricated from iron sheets. The procedure is started with modelling and analyzing the product. It involves shearing and shaping pieces, welding them together and grinding and polishing the welded areas afterwards. It ends with implementation of inserts and installing the frame and the clampings.

فارسی

فارسی