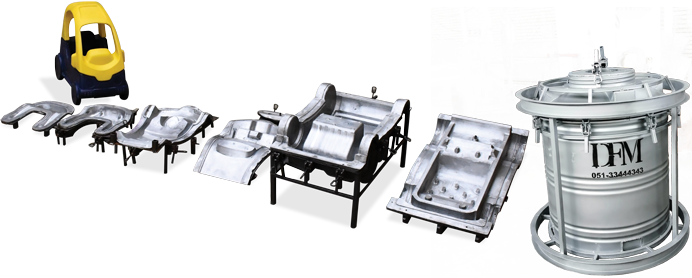

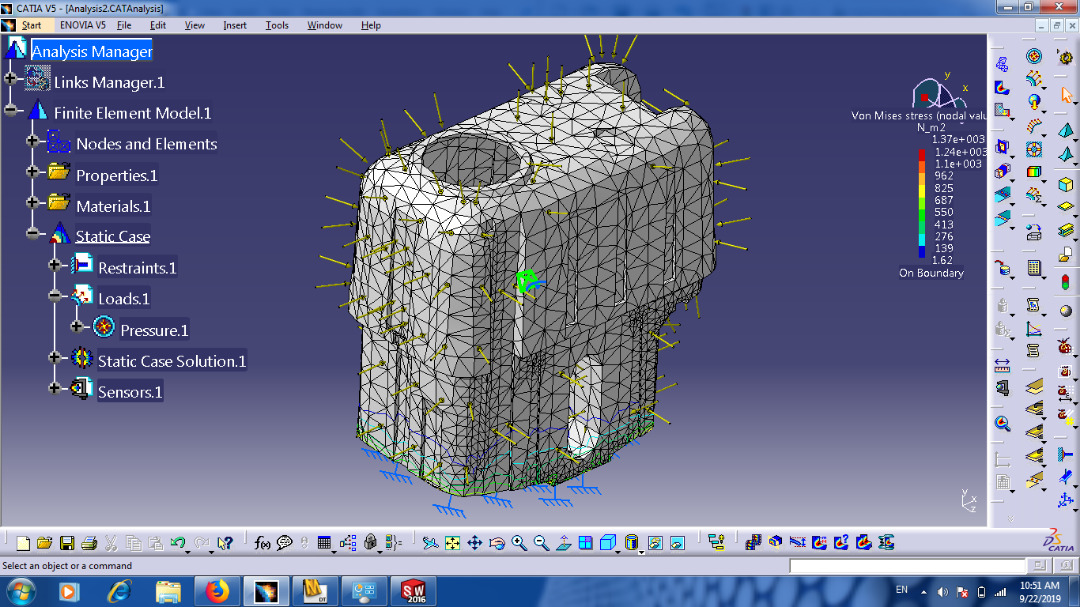

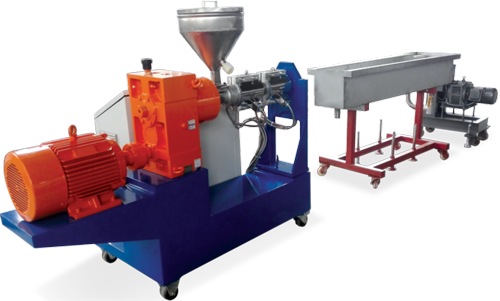

PLASTIC DAMPER ALUMINUM MOLD

Manufactured in Davaran Fidar Maham Co.

To avoid damaging machines, instruments, cars and etc. in parking’s, factories and etc. the plastic dampers are mounted on walls or areas with sharp edges.

Listed below are benefits of polyethylene, the material used in making this product:

- UV resistant

- Resistant to moisture and to different temperatures which make it usable outdoor.

- High tension and impact resistance.

Damaged products are easily repairable

فارسی

فارسی