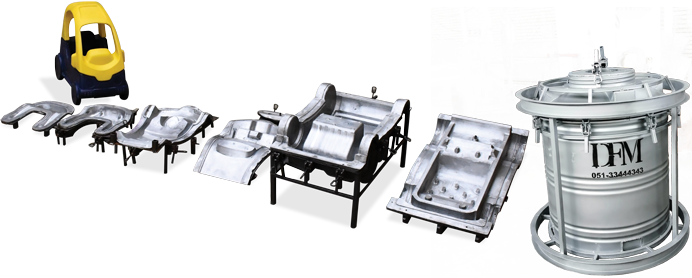

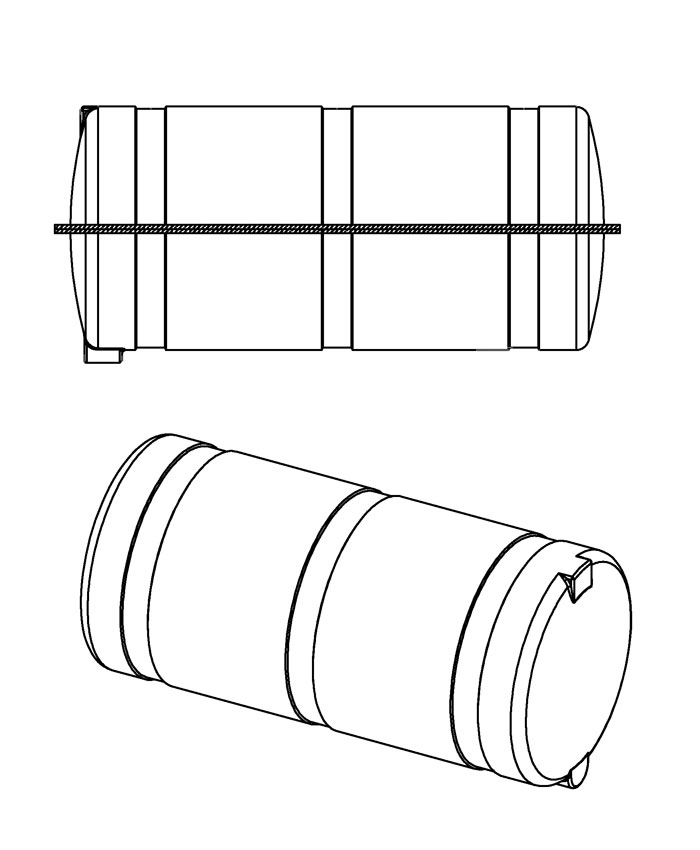

Side Mount Truck Tank Mold

Manufactured in Davaran Fidar Maham Co.

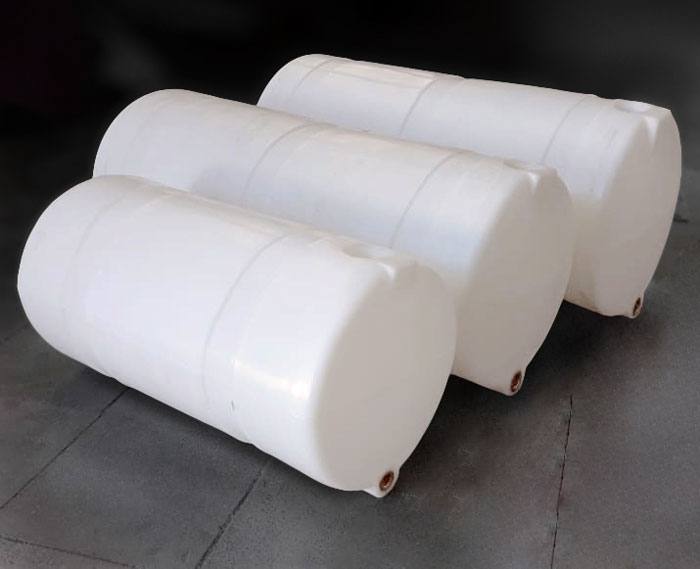

Side mounted truck tanks, as the name implies, are for storing water, fuel, or other fluids underneath the trucks. A variety of dimensions are also available for different trucks.

The products mold is fabricated from iron sheets. The roto mold making process involves modelling of the product as the first step. Followed by shearing and shaping the sheets, they are welded together and the welded areas are then grinded and polished. And as the final step the inserts, clampings, and the frame are implemented and installed and the mold would be ready to use. Customer’s brand and/or additional texts can also be embossed or debossed on the products surface.

فارسی

فارسی