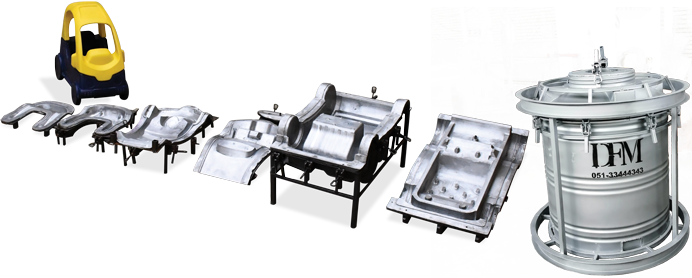

Simple steel injection molds

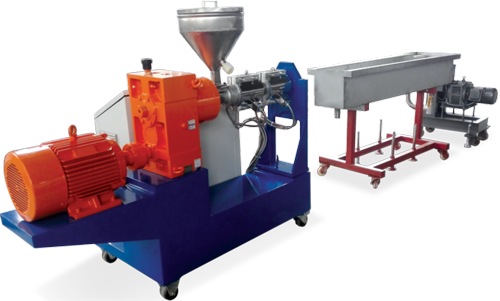

One method of production is to make parts with materials that can be injected into the cavity of a mold. The main materials that can be injected include metals, glass, elastomers and most hard heat and soft heat polymers common in the market. These materials are first heated in a chamber and mixed together, then pressed into the mold cavity. There they cool, harden, and take on the geometric shape of the mold cavity. The method is that the product is first designed by an industrial designer or engineer and then the related molds are made by the mold maker. The molds are made of metal and are usually made of steel or aluminum, which is carefully machined to form the desired part.

Injection molding is widely used in the manufacture of various parts. From the smallest part of the car to the whole body of the car. Parts produced by injection molding must be carefully designed to simplify the molding process. The materials to be used must be examined and calculated in terms of the appearance and properties of the manufactured part.

فارسی

فارسی