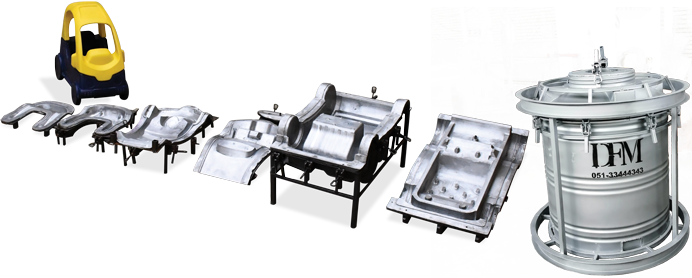

IRON SHEET ROTATIONAL MOLDING

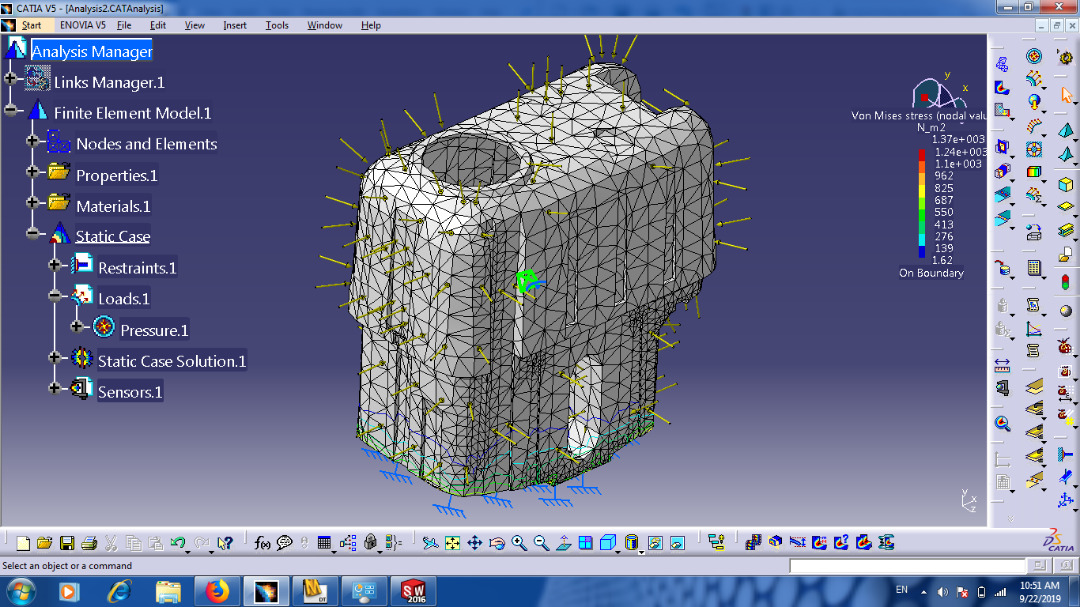

They are usually used to produce parts that are complex and have special shapes or the quality of the final product is important to us; these molds require three-dimensional modeling design, iron sheet casting and finally cnc machining.

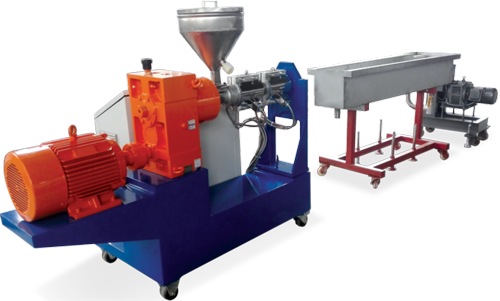

For the production of tanks and plastic parts by rotary molding, a mold with the desired design and shape is required.

All kinds of molds are used in the production of bulky plastic parts.

The type of mold depends on the project budget, product complexity and production run. They usually produce complex parts with asymmetric angles with aluminum molds.

Larger and simpler products such as water tanks, bathtubs and the like are produced with iron sheet molds.

In cases where we want the same parts to be produced with better quality or with more circulation, we use steel sheet molds.

Iron sheet molds can be produced in capacities of 50 to 6500 liters.

These molds are economical and inexpensive.

We use this type of molds for products that need to be produced in low circulation or we need to update the product model regularly.

Large water and sewage tanks are also commonly used with iron sheet molds.

فارسی

فارسی