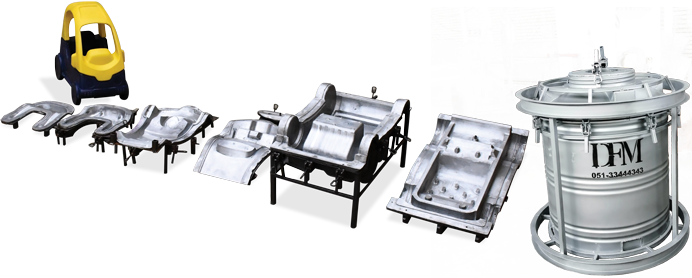

Steel Blow molding

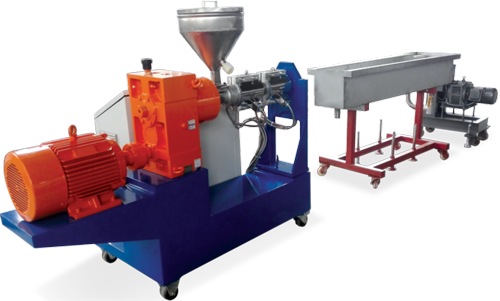

The molding process of steel pneumatic molds begins with heating the plastic and creating the initial bite. The initial bite is a cylinder with a free end with a hole through which air can pass, then the bite is placed inside the mold and the wind is blown into it. The air pressure pushes the plastic and sticks it to the wall of the mold. After the plastic cools and cools, the mold opens and the piece comes out. In the other two methods, the morsel is created by injection in a special mold. In the blowing stage of the last method, ie tensile injection molding, a rod of the heated morsel is pulled and at the same time air is blown in it.

فارسی

فارسی