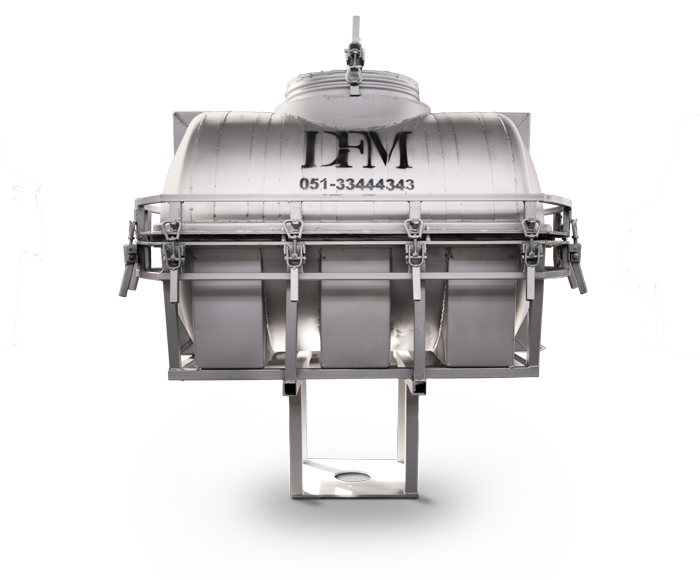

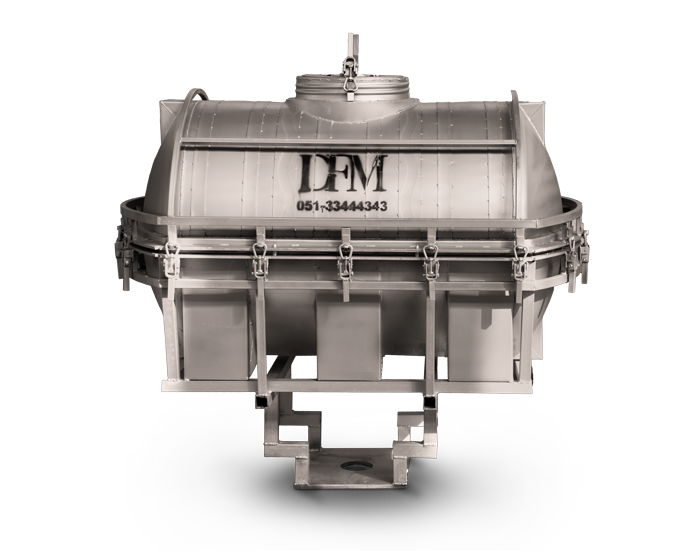

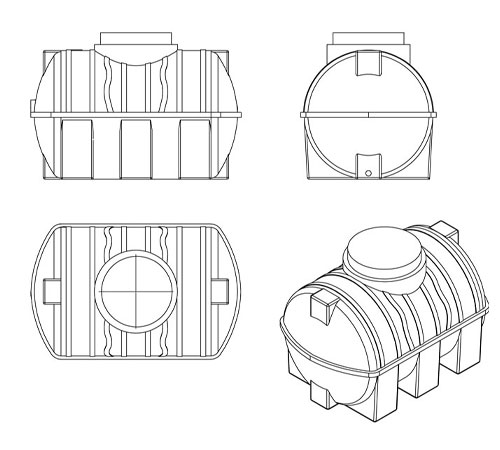

500 Liters Horizontal Tank Mold Type B

Designed and manufactured in Davaran Fidar Maham Co.

Suitable for places where you have height limits. The tank is designed to have no water spillage in transportation. Thanks to in-built feet there’s no need for additional holders.

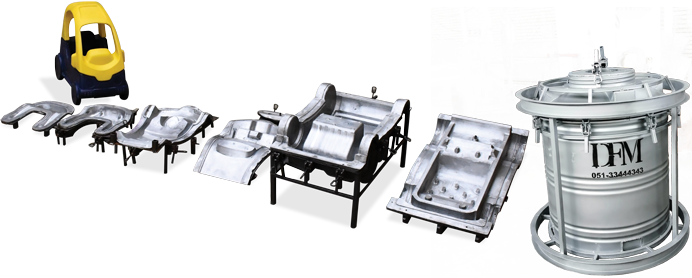

The rotational mold of this product is fabricated from iron sheets. The pieces are welded together afterwards followed by grinding and polishing the mold’s surface. As the final step the clamping system and the frame will be added.

فارسی

فارسی