5000 Liters Tank Rotational Mold

Manufactured by Davaran Fidar Maham Co.

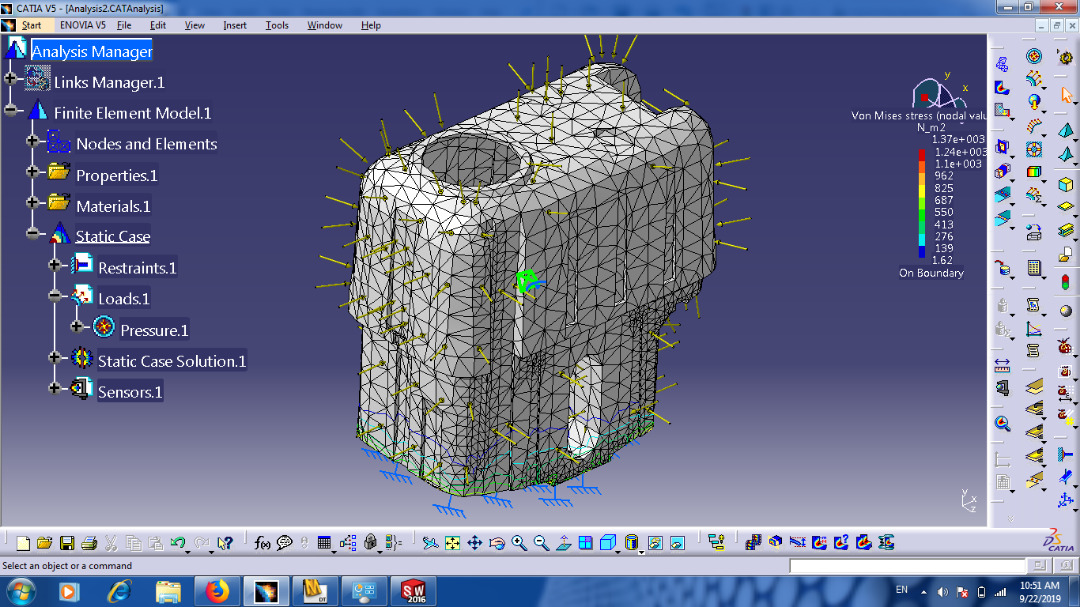

The plastic tank, being approximately 2m high with a radius of 1.7m, is specially designed to enhance durability and strength by using the least amount of raw material. If height isn’t a problem in your storage place then vertical tanks are a better pick since you are able to fit more vertical tanks than horizontal tanks in an area.

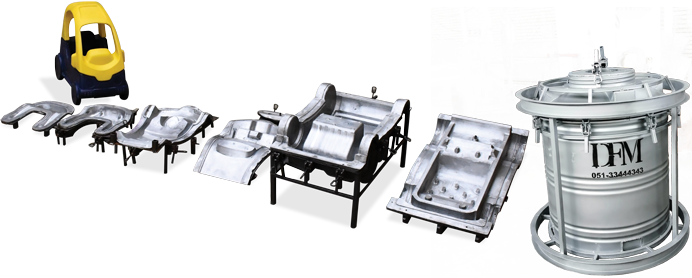

5000 liter tank’s roto-mold has been fabricated from iron sheets. The process includes modelling the product, shearing the metal sheets, welding, adding the inserts, adding the frame and the clamps, and finalizing the mold. Custom brand and/or additional texts can be embossed or debossed on the final.

فارسی

فارسی