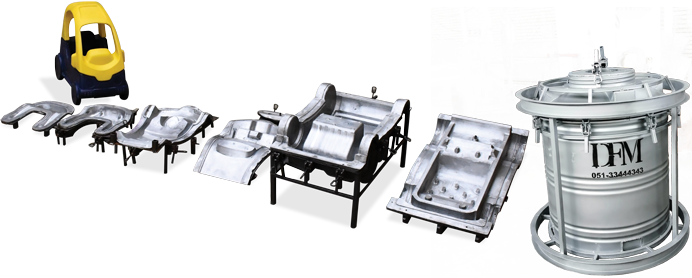

800 LITERS MOUNTED SPRAYER TANK

manufactured in Davaran Fidar Maham Co.

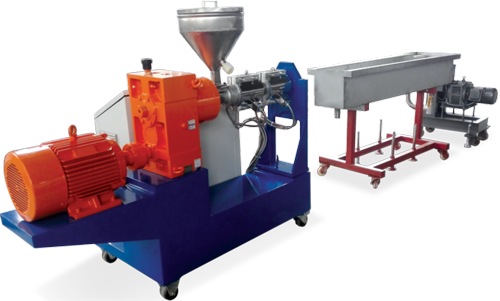

800L mounted sprayer tank, designed to exert the minimum force on tractor arms, comes in polyethylene, the most common raw material used in rotational molding because it’s:

- UV resistant.

- Corrosion resistant. Therefore a wide range of fluids, from aggressive compounds to drinkable water, can be contained without any chemical disturbances.

- Durable due to high yielding stress and impact strength.

- Usable outdoors in different weather conditions.

- Can be repaired without effort.

فارسی

فارسی