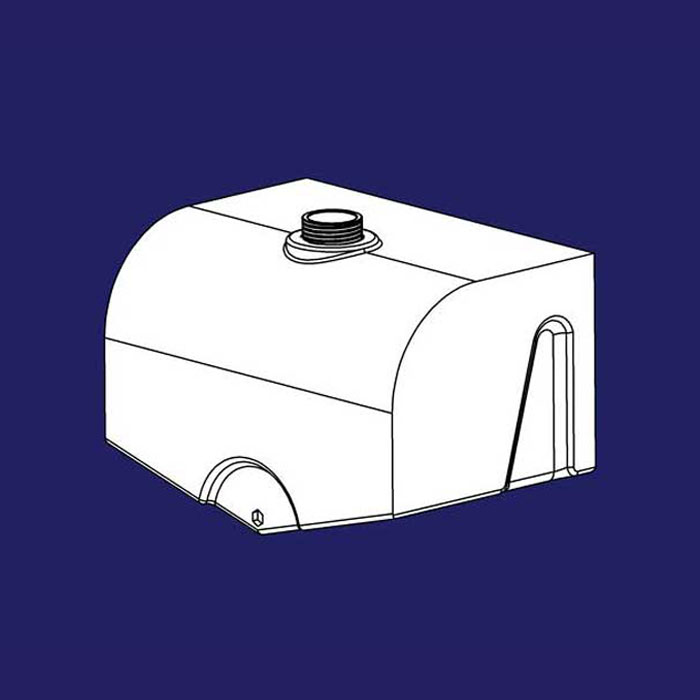

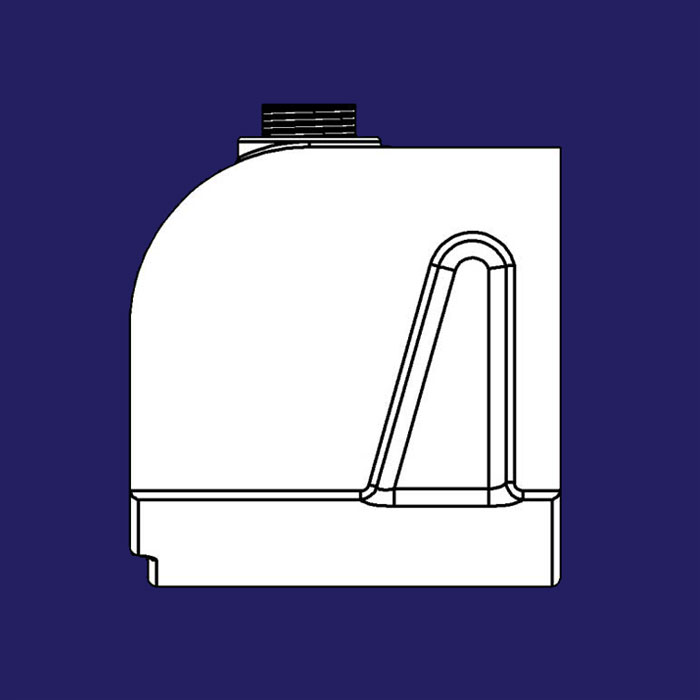

HANDWASHING TANK FOR 800 LITERS MOUNTED SPRAYER TANKS

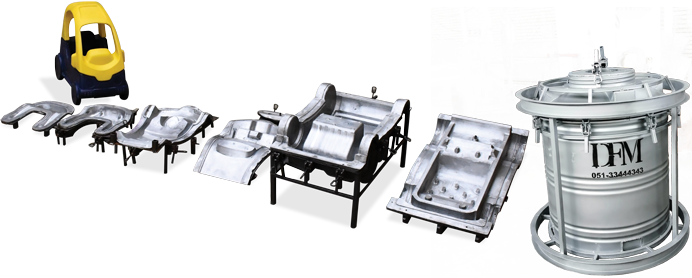

Manufactured in DFM Co.

An 800L mounted sprayer tank is made up of 3 parts; one which contains the main spraying components and the other two where one contains components to rinse the main tank, usually at the end of each working session to eliminate any residues and the other one containing clean water for washing purposes.

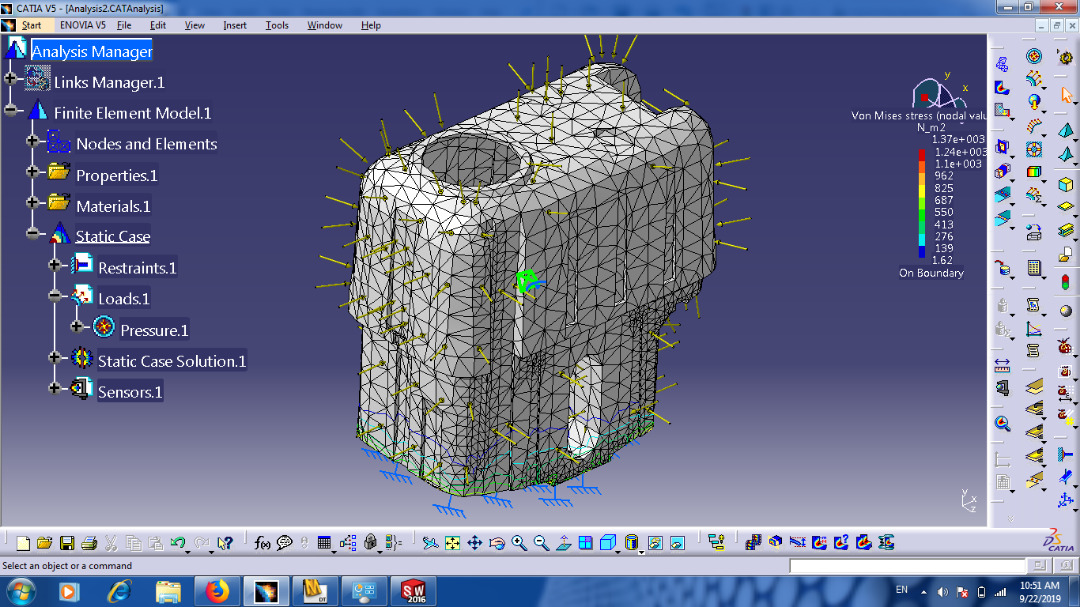

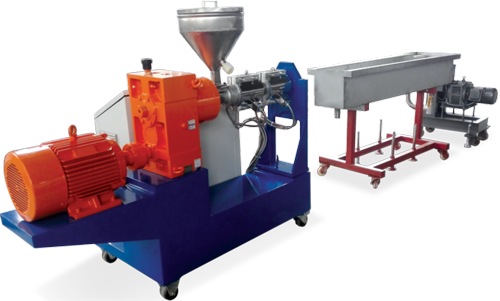

The handwashing tank is rotational molded. The rotational molding, one the several plastic manufacturing techniques, is the pick when one needs hollow parts up to 50,000L capacity. The procedure is a lot more cost efficient compared to other techniques and is beneficial even in low volume manufacturing.

فارسی

فارسی