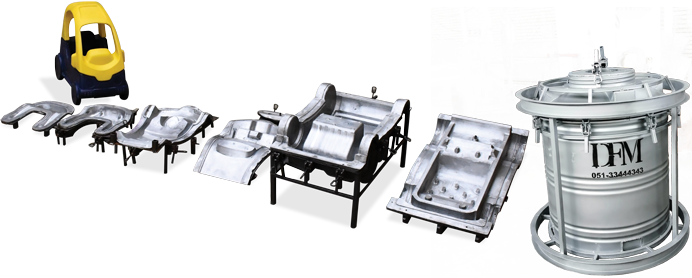

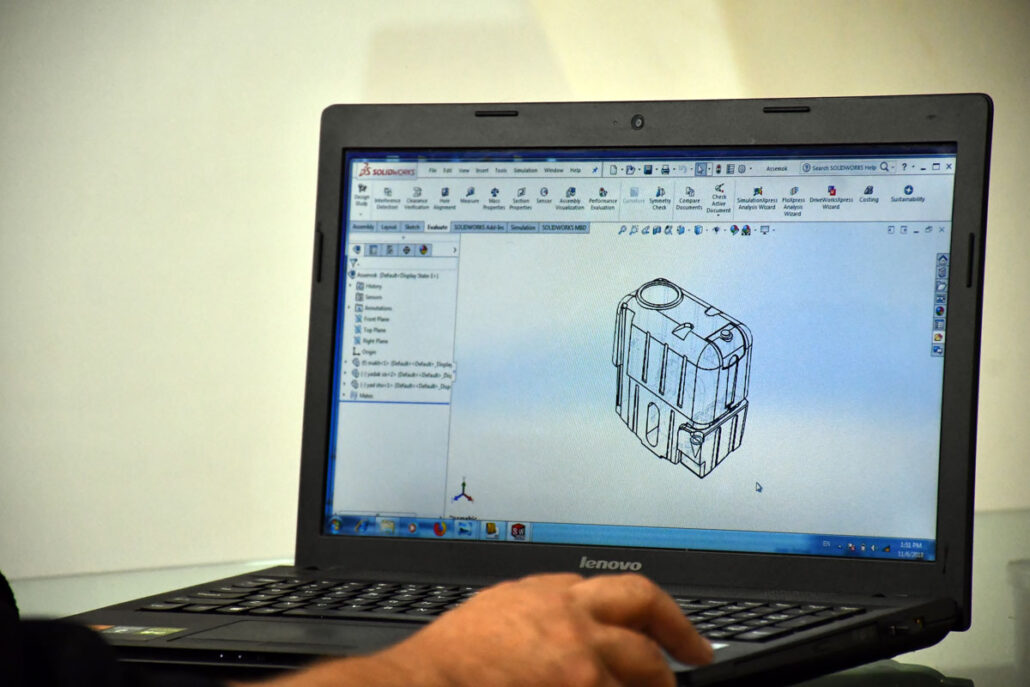

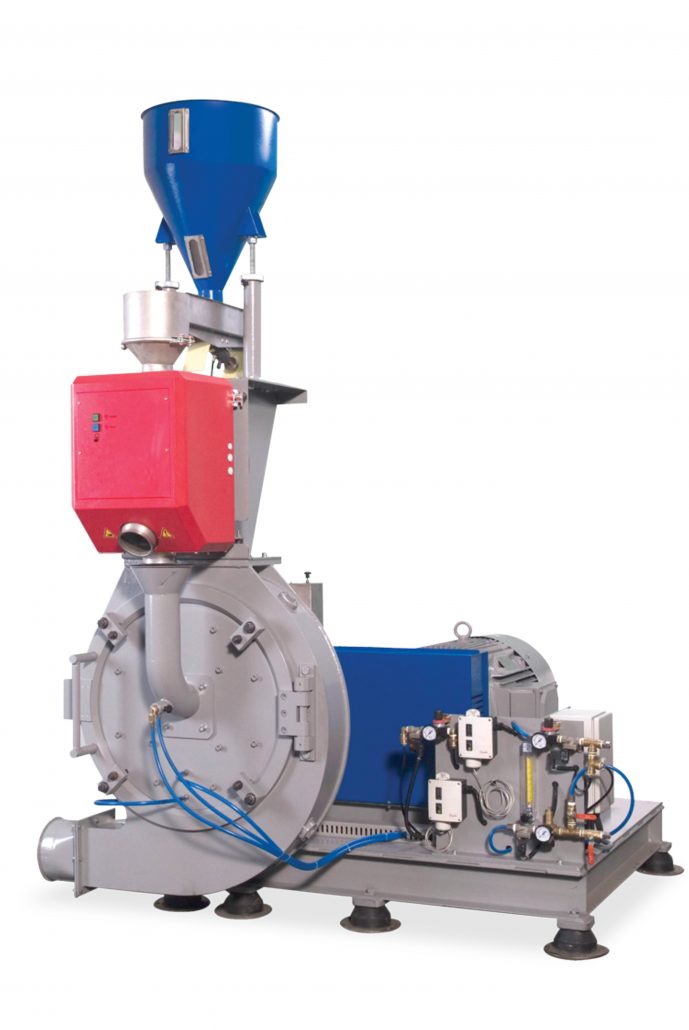

Shuttle Rotational molding machine

Shuttle Roto-molding machine works with a central oven and two carts on sides with offset, C shaped, and/or straight arms. Shuttle machines can also be manufactured with 4 arms. The straight arms are used for multiple smaller molds while Offset or C shaped arms are suitable for bigger and/or asymmetric molds.

فارسی

فارسی