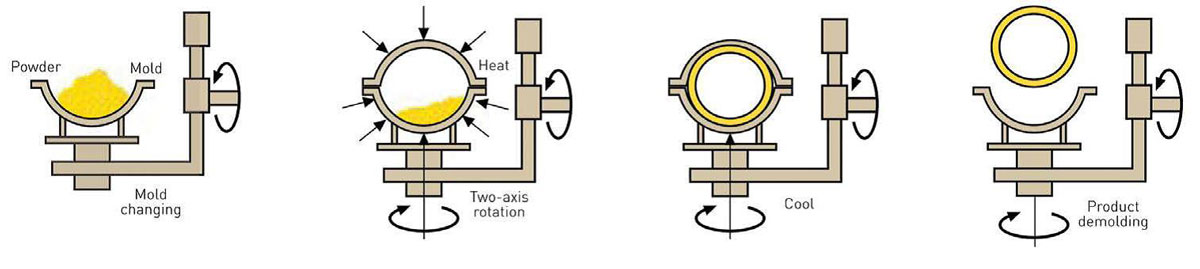

Rotational molding is a method of production in the polymer industry, which is said to be in the desired shape, which is already installed on an arm and filled with raw materials, which is usually polyethylene powder, and then sent into the kiln. The oven is heated to 200 to 270 degrees Celsius with a centrifugal force that is baked in a specific time by rotating the arm 360 degrees in both vertical and horizontal directions. The mold is then cooled by the wagon out of the kiln in the refrigeration area with the relevant fans. After the molds have cooled, the product is emptied from the molds, folded and ready to be delivered to the consumer

[/col] [/row]

More freedom in design

Your designer has complete freedom in designing the mold to produce the piece in a circular manner. Angles, depressions and

Bumps in other plastics production methods are always limited. Also in others

Methods After designing the mold thickness is fixed and unchangeable. While in the thick circular method

It can be changed arbitrarily and frequently.

Production of two-layer, three-layer and multi-layer product

In the circular method, the production of multilayer products can be done easily. If in other techniques

We need special molds for multi-layer production.

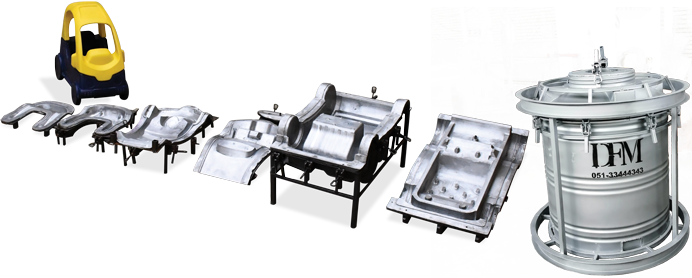

Making different types of molds, with different materials according to the customer’s request

Highest quality / lowest price

Fast and cost-effective mold production

We have our own mold production unit, so designing and producing molds is very fast and cost-effective

Is . In general, in a rotary molding system, turning an idea into a desired product is cheap and fast

And it is more available in the company of Doran Fidar Maham.

Easy planting of metal parts in the product

Planting inserts in crops is easy. Compared to other plastic production techniques

It is economical and durable.

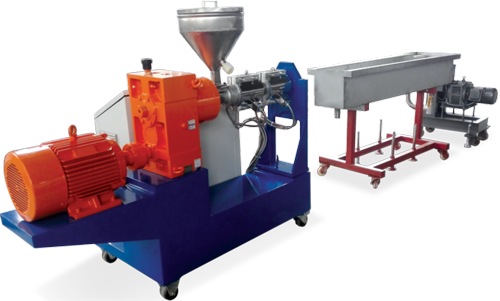

Design and manufacture of machines for the production of tanks and the production of tanks and bulk polymer parts by the rotary method

Production of large parts with large dimensions

In the rotational plastic molding method, we have the ability to produce very large products. We can

Produce a piece with dimensions of 4 meters 4 x meters 4 x meters up to a capacity of 65,000 liters and a weight of 1,500 kg.

Durable and recyclable

Parts produced in the rotary method are very durable due to the special production process and in open environments

And can be used in contact with chemicals for a long time. Also these parts are easily removable

Are recycled.

Produced in different colors even with small numbers and low circulation

You may want to produce several different colors of your desired product in a small circulation

do . This request can be easily implemented in the rotary molding system.

Produce a small number of pieces

In the rotary method, we can produce low-volume parts even under 50 pieces, while in other techniques

It is not economical to inject a circulation of less than 1000 copies.

فارسی

فارسی